Shop By Category

Related Links

Punch Tools provides high-efficiency secondary processing for all aluminum profiles. Our specialized tooling ensures that complex cuts never compromise the structural integrity or legs of your parts.

Aluminum Extrusion Punching

Punching

Holes, slots, or complex cluster patterns in aluminum extrusion.

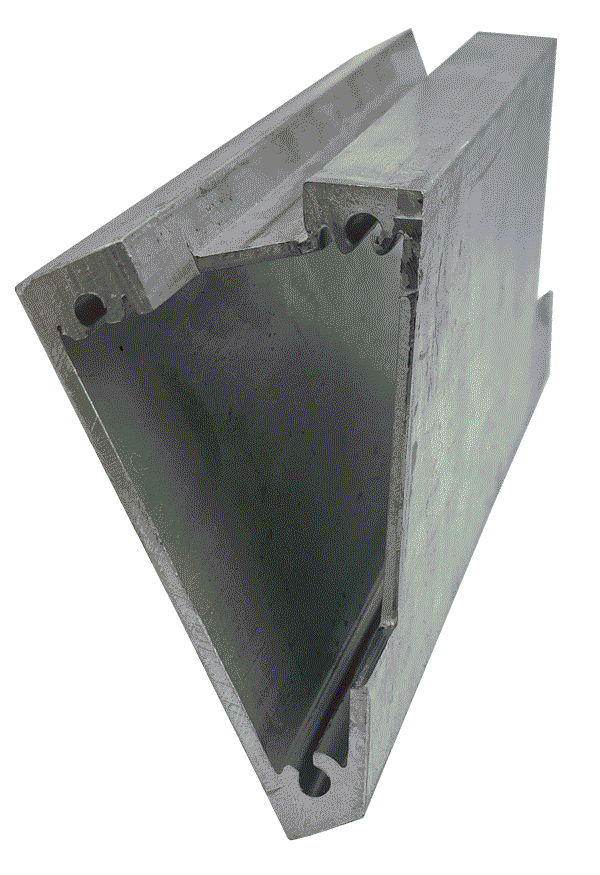

Notching

V-notches, corner notches (to join two pieces together), or side-wall removal.

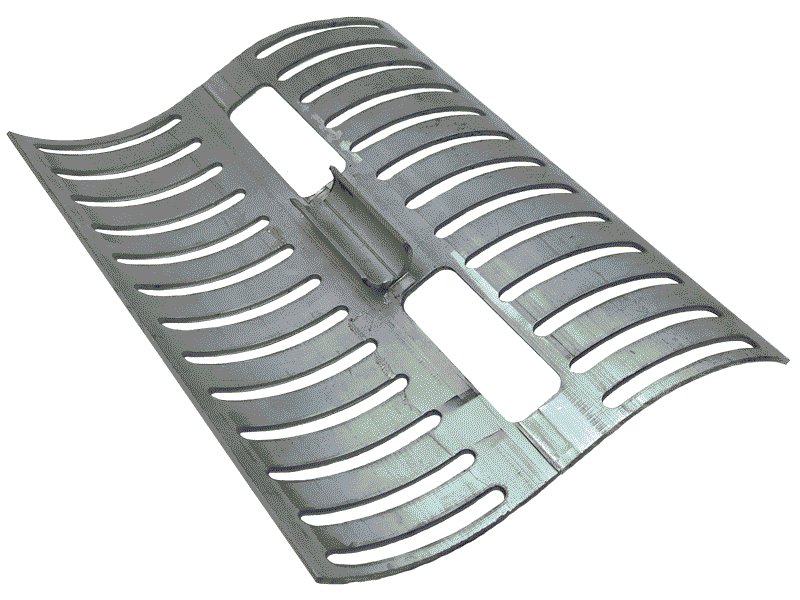

Gang Punching

Custom cluster pattern punch for aluminum extrusion.

We Work With All Aluminum Profiles:

Structural Shapes

- Angles: Any size or degree.

- Channels: Any shape or depth.

- I-Beams & H-Beams: Heavy-duty structural support.

- T-Bars & Z-Bars: Mounting and transition profiles.

- Solid Bars: Flat, round, or hex stock.

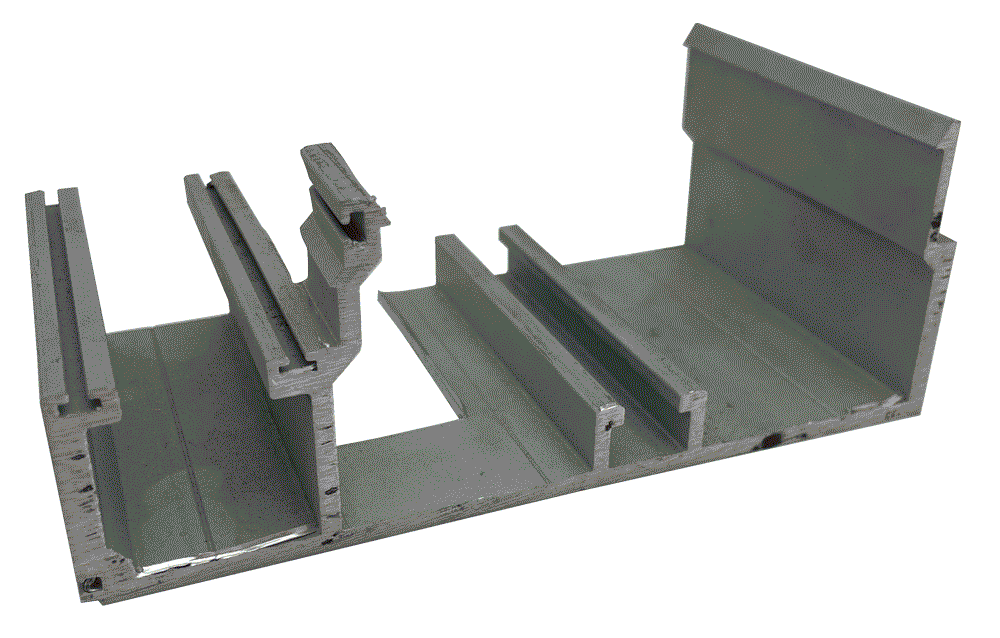

Custom Aluminum Extrusions

- Construction: Door sills, window frames, and curtain walls.

- Industrial: Computer chassis, truck trailers, and ladders.

- Home & Office: Kitchen components and cabinet profiles.

Tubing & Pipe

- Round, square, or rectangular hollow tubes.

|

|

|

|

|

We can handle any aluminum part, providing precision and durability for your fabrication requirements.

Why Punching Beats CNC Machining

When it comes to "secondary processing" (the finishing touches on your aluminum), punching is the fastest and most cost-effective method available.

1. Incredible Speed

-

The Punching Advantage: We can create multiple holes and complex notches in a single 5-second stroke of the press.

-

The CNC Disadvantage: A CNC drill has to move to every single hole location one by one, which can take several minutes per part.

Bottom Line: Punching is often 20x to 50x faster than drilling or milling.

2. Complex Notches Made Easy

Inside corners are notoriously difficult and slow to "dig out" with a spinning drill bit. Our custom punch tools snap these shapes out instantly, leaving a clean, precise edge every time.

3. "One-and-Done" Efficiency

With Gang Punching, we don't just do one hole at a time. We can set up a tool that punches an entire pattern of holes and notches all at once. This removes the need for:

-

Time-consuming CNC programming.

-

Slow drilling processes.

-

Expensive "de-burring" (cleaning up the messy metal shavings left by drills).

4. Precision for Tight Spaces

Because our tools are custom-built, we can reach into narrow channels and achieve tight details—like a 0.5-inch radius—without the tool "wandering" or vibrating like a drill bit might.

Click here to learn more about creating your own bench-top press models.

Click here to learn more about creating your own high-tonnage press solutions.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996